Why is Wire Brushing Necessary?

The calcification must be wite brushed of so the sealant has something to adhere two.

Before applying any waterproofing solutions to basement walls, it’s essential to ensure the surface is clean and free of debris. Cement blocks, often used in basement construction, can accumulate dust, dirt, mold, efflorescence (white, chalky salt deposits), and loose mortar over time. These substances can create barriers that prevent waterproofing coatings from adhering properly to the wall surface.

Wire brushing the cement blocks serves multiple purposes:

- Removing Loose Debris: Over time, particles can accumulate on the walls, compromising the bond between the waterproofing material and the concrete. Wire brushing removes these contaminants, ensuring a strong, long-lasting adhesion.

- Eliminating Mold and Mildew: Mold spores can easily grow on damp, dirty surfaces. Brushing away existing mold and mildew helps create a clean environment where waterproofing solutions can effectively seal out moisture.

- Preparing for Better Adhesion: A rough, clean surface enhances the bonding capability of waterproofing materials. Brushing the cement blocks creates a textured surface that promotes better adherence, leading to a more durable waterproof seal.

How to Wire Brush Cement Blocks for Basement Waterproofing

Tools and Materials Needed:

- Wire brush (handheld or attached to a power drill)

- Dust mask

- Safety goggles

- Gloves

- Shop vacuum or broom

- Drop cloth or plastic sheeting

Step-by-Step Process:

- Safety First: Wear a dust mask, safety goggles, and gloves to protect yourself from dust, debris, and mold spores. This is crucial because mold can cause respiratory issues, and loose particles can irritate the eyes and skin.

- Prepare the Area: Lay down a drop cloth or plastic sheeting to catch falling debris and dust. This will make cleanup easier and prevent the spread of contaminants to other parts of your home.

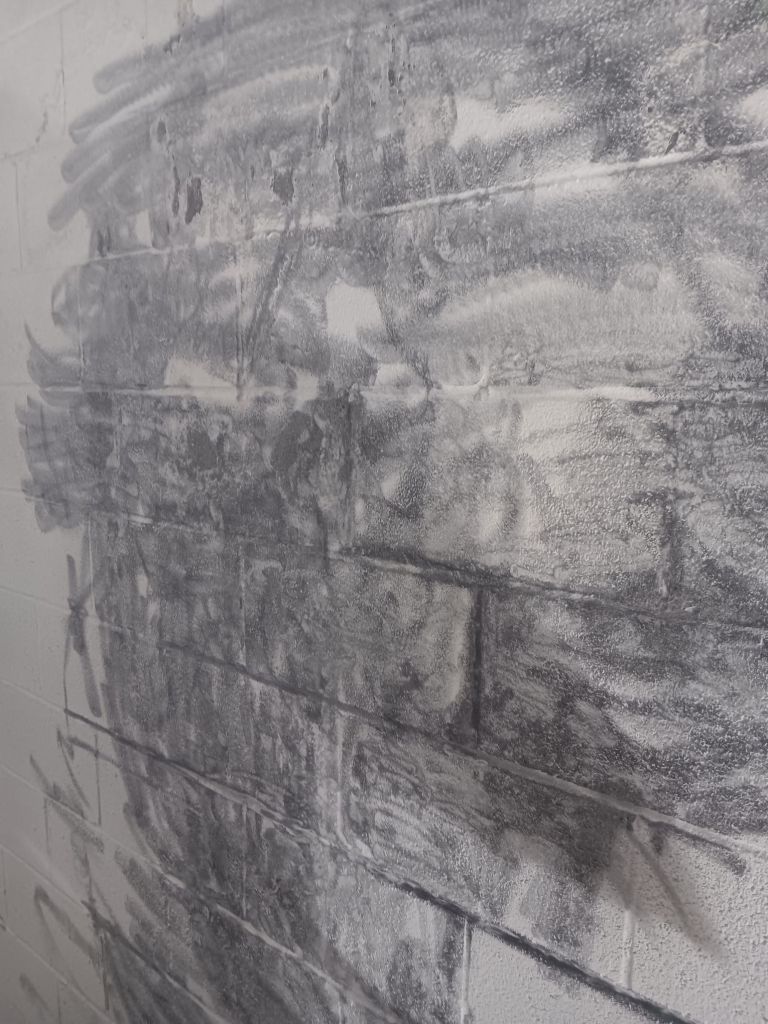

- Start Brushing: Using a wire brush, begin scrubbing the cement blocks in a circular motion. If using a handheld wire brush, apply firm pressure to dislodge dirt and loose material. For larger areas, consider using a wire brush attachment on a power drill for faster and more efficient cleaning.

- Focus on Problem Areas: Pay special attention to areas with visible mold, efflorescence, or crumbling mortar. These spots may require additional brushing to remove all contaminants.

- Clean as You Go: Use a shop vacuum or broom to regularly remove dust and debris from the surface. This prevents buildup and allows you to see which areas still need more work.

- Inspect Your Work: After brushing the entire surface, inspect the walls closely. Look for any remaining dirt, mold, or loose mortar. Re-brush any spots that still have visible contaminants to ensure a clean surface.

- Final Cleanup: Once all the cement blocks are brushed clean, vacuum or sweep the floor to remove any fallen debris. Make sure the area is thoroughly cleaned before proceeding with the next step in the waterproofing process.

Conclusion

Wire brushing the cement blocks in your basement is a crucial step in preparing for effective waterproofing. By removing dirt, mold, and other contaminants, you create a surface that allows waterproofing solutions to adhere properly and form a long-lasting barrier against moisture intrusion. Taking the time to properly prepare your basement walls not only enhances the effectiveness of the waterproofing process but also helps protect the structural integrity of your home.

At Property Damage Solutions in Richmond, Kentucky, we understand the importance of thorough preparation in every restoration project. Our team of certified professionals is here to help you ensure your basement stays dry and safe. Contact us today for expert basement waterproofing services and peace of mind knowing your home is protected from moisture damage.

Leave a comment